Hello vector,

We haven’t made the modification yet as we don’t have the part and the microsoldering tool, our soldering iron is way too big for this operation right now. I’ll come back to you when we have done it!

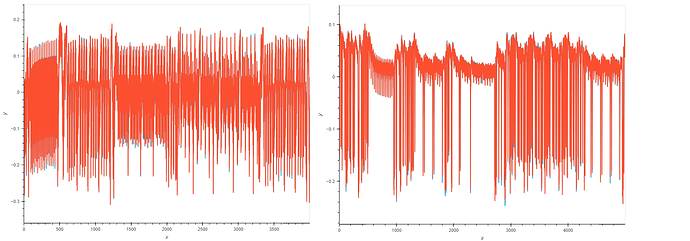

I have now compared my traces with the traces from the “simulated” lab and found that these do not show the significant negative drops I see in my traces. See below simulated traces on the left and the measurements from my Husky on the right:

Overall signal level seems to be lower as well, but that may be related to the reduced gain I applied in order to reduce the risk of running into errors (as @Shanly described above).

Other than the gain value, I use the standard startup and solution scripts. The CW reports VCCaux error at every startup, but it can be cleared and doesn’t return until the next restart.

Any suggestions what I can do to improve my setup?

I wouldn’t recommend trying to compare to the simulated labs, as they’re done with a completely different target (the STM32F3)

Thanks @Alex_Dewar, that makes sense. Is there a possibility that the VCCaux alarm has something to do with this behavior? I get the following reported when checking print(scope.errors) at startup

XADC errors = VCCaux alarm,

ADC errors = False

extclk error = False

trace errors = False

Clearing with scope.XADC.status = 0 as defined in the docs seems to be successful.

Would anyone be able to share settings and a plot of traces of a successful run of Lab 3_3 with a v3 Husky?

I feel I have tried every possible setting and configuration in last six weeks and would like to make sure it is not a(nother) hardware issue.

The VCCaux alarm is sticky until you clear it. When does it happen? And what is the output of this when after it’s happened:

print(scope.XADC.get_vcc('vccaux', 'current'))

print(scope.XADC.get_vcc('vccaux', 'min'))

print(scope.XADC.get_vcc('vccaux', 'max'))

It’s not likely to be the cause for the issue you’re seeing, but it is curious.

What capacitor value did you use?

Try this notebook and report what you get for sad and std.

notebook.zip (1.9 KB)

Thanks @jpthibault. I really appreciate your support.

I am checking the scope.errors right before starting to capture the traces, check the current value of VCCaux and then reset the error. Running scope.XADC.get_vcc('vccaux') with a second argument (current, min, max) doesn’t work for some Python reason, reporting that the function receives three instead of one or two arguments. ![]()

Below my output:

XADC errors = VCCaux alarm,

ADC errors = False

extclk error = False

trace errors = False

1.806884765625

Running scope.XADC.status = 0 ...

Done

XADC errors = False

ADC errors = False

extclk error = False

trace errors = False

1.808349609375

Looks stable from my perspective, min and max would be helpful for sure. I will try to find the issue here.

The capacitor I used is a 100pF X7R 50V from a trusted source and the improvement on the CPA lab was quite significant, while for Lab 3_3 it is not visible.

I executed the notebook (had to adjust some paths to match my installation) and received the following output:

std = 24.10216651470951, (0.06469655183900855 scaled)

0.006814599609375

sad = 25.33721142578123

std = 24.10216651470951

I would love to say that I was smart enough to understand these values and draw my conclusions… but I am not. What can you read from this?

You must be using an older release; use the develop branch.

That’s in line with what we’ve seen.

You should be able to succeed with the DPA attack. Could be a ghost peak problem; could be more traces are needed.

Thanks @jpthibault.

With all other potential issues out of the way, I finally solved it:

It was indeed a ghost peak problem. With my limited experience in power analysis, I wasn’t aware of the magnitude of ghost peaks. What I formerly though was the AES algorithm and lead to significant spikes in the plot turned out to be something completely different. The actual AES spikes where hiding somewhere in the noise (the actual peak is at sample 1900 rather than 1250 or 4300).

With the full_diffs_list plot in the Ghost Peaks chapter

fig = cw.plot()

for subkey in range(0, 16):

fig *= cw.plot(full_diffs_list[subkey][known_key[subkey]])

fig

I finally received the following result:

zooming in on the now colorful peaks:

Setting the following parameters before sampling helped me to window the correct range:

scope.adc.offset = 1800

scope.adc.samples = 900

Big thanks to the NewAE team for the great support and patience.

I have the Husky HWREV 1.1C, and need a lot more traces on Lab 3.3, as well as 4.2 compared to what’s mentioned in the notebook. Is adding the capacitor mentioned above a recommended solution?

Edit: When I change the ADC offset and samples as per above (to 1800 and 900 respectively), it seems Lab 4.2 actually works with only 50 traces. But I’m not sure why ![]()

The capacitor improved the performance of Lab 4_2 significantly in my case. For Lab 3_3 I didn’t see any improvement.

The values for offset and no of samples, i.e. start and duration of analyzed section, in Lab 3_3 in the example above were chosen to select exactly the shown 16 peaks and filter out the much larger ghost peaks at 1300 and 4300.

I would assume that due to the very similar timing of the target firmware in Lab 3_3 and 4_2, the time window of leakage might also be similar.

Thanks! Yes, that does make a lot of sense regarding the ADC parameters. I’ll consider making the HW changes then to see if there are any changes in the performance.

Hello,

Sorry for the delayed answer, we finally managed to perform the modification.

This happened when attempting to validate the hardware:

import chipwhisperer as cw

scope = cw.scope()

(ChipWhisperer Scope ERROR|File __init__.py:389) ChipWhisperer error state detected. Resetting and retrying connection...

---------------------------------------------------------------------------

OSError Traceback (most recent call last)

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\__init__.py:387, in scope(scope_type, name, sn, idProduct, bitstream, force, prog_speed, **kwargs)

386 try:

--> 387 rtn.con(**kwargs)

388 except IOError:

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\OpenADC.py:662, in OpenADC.con(self, sn, idProduct, bitstream, force, prog_speed, **kwargs)

661 self.la_mmcm = XilinxMMCMDRP(self.la_drp)

--> 662 self.clock = ChipWhispererHuskyClock.ChipWhispererHuskyClock(self.sc, \

663 self._fpga_clk, self.glitch_mmcm1, self.glitch_mmcm2)

664 self.ADS4128 = ADS4128Settings(self.sc)

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:712, in ChipWhispererHuskyClock.__init__(self, oaiface, fpga_clk_settings, mmcm1, mmcm2)

711 self.naeusb = oaiface.serial

--> 712 self.pll = CDCI6214(self.naeusb, mmcm1, mmcm2)

713 self.fpga_clk_settings = fpga_clk_settings

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:36, in CDCI6214.__init__(self, naeusb, mmcm1, mmcm2)

35 self._mmcm_vco_max = 1200e6

---> 36 self.setup()

37 self.set_pll_input()

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:144, in CDCI6214.setup(self)

143 # disable GPIO1/4 as inputs

--> 144 self.update_reg(0x00, (1 << 13) | (1 << 12), 0)

146 self.update_reg(0x04, (1 << 3) | (1 << 4), 0) # turn off outputs 2 and 4

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:119, in CDCI6214.update_reg(self, addr, bits_to_set, bits_to_clear)

118 # print(bits_to_set, bits_to_clear)

--> 119 reg_val = self.read_reg(addr, as_int=False)

120 reg_val[0] &= 0xFF - bits_to_clear[0] # the not we want ;)

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:80, in CDCI6214.read_reg(self, addr, as_int)

79 if data[0] != 2:

---> 80 raise IOError("PLL/I2C Error, got {}".format(data))

82 if as_int is True:

OSError: PLL/I2C Error, got bytearray(b'\x01\x08\x00')

During handling of the above exception, another exception occurred:

OSError Traceback (most recent call last)

Cell In[3], line 2

1 import chipwhisperer as cw

----> 2 scope = cw.scope()

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\__init__.py:393, in scope(scope_type, name, sn, idProduct, bitstream, force, prog_speed, **kwargs)

391 time.sleep(2)

392 rtn = scope_type()

--> 393 rtn.con(**kwargs)

394 return rtn

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\OpenADC.py:662, in OpenADC.con(self, sn, idProduct, bitstream, force, prog_speed, **kwargs)

660 self.glitch_mmcm2 = XilinxMMCMDRP(self.glitch_drp2)

661 self.la_mmcm = XilinxMMCMDRP(self.la_drp)

--> 662 self.clock = ChipWhispererHuskyClock.ChipWhispererHuskyClock(self.sc, \

663 self._fpga_clk, self.glitch_mmcm1, self.glitch_mmcm2)

664 self.ADS4128 = ADS4128Settings(self.sc)

665 self.XADC = XADCSettings(self.sc)

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:712, in ChipWhispererHuskyClock.__init__(self, oaiface, fpga_clk_settings, mmcm1, mmcm2)

710 self.oa = oaiface

711 self.naeusb = oaiface.serial

--> 712 self.pll = CDCI6214(self.naeusb, mmcm1, mmcm2)

713 self.fpga_clk_settings = fpga_clk_settings

714 self.fpga_clk_settings.freq_ctr_src = "extclk"

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:36, in CDCI6214.__init__(self, naeusb, mmcm1, mmcm2)

34 self._mmcm_vco_min = 600e6

35 self._mmcm_vco_max = 1200e6

---> 36 self.setup()

37 self.set_pll_input()

38 self.set_outdiv(3, 0)

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:144, in CDCI6214.setup(self)

131 """Do required initial setup.

132

133 Does the following:

(...)

141 * Use register to select PLL input instead of pin

142 """

143 # disable GPIO1/4 as inputs

--> 144 self.update_reg(0x00, (1 << 13) | (1 << 12), 0)

146 self.update_reg(0x04, (1 << 3) | (1 << 4), 0) # turn off outputs 2 and 4

148 self.update_reg(0x05, 0, 0b11111110111) # turn on power to everything

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:119, in CDCI6214.update_reg(self, addr, bits_to_set, bits_to_clear)

116 bits_to_clear = tmp

118 # print(bits_to_set, bits_to_clear)

--> 119 reg_val = self.read_reg(addr, as_int=False)

120 reg_val[0] &= 0xFF - bits_to_clear[0] # the not we want ;)

121 reg_val[1] &= 0xFF - bits_to_clear[1]

File c:\users\\chipwhisperer5_64\cw\home\portable\chipwhisperer\software\chipwhisperer\capture\scopes\cwhardware\ChipWhispererHuskyClock.py:80, in CDCI6214.read_reg(self, addr, as_int)

77 data = self.naeusb.readCtrl(0x29, dlen=3)

79 if data[0] != 2:

---> 80 raise IOError("PLL/I2C Error, got {}".format(data))

82 if as_int is True:

83 return (data[1]) | (data[2] << 8)

OSError: PLL/I2C Error, got bytearray(b'\x01\x08\x00')

The Husky was working fine before. Do you know why this is happening ? This is the part we used for our modification: https://www.mouser.se/ProductDetail/KEMET/C0402C101K5TACAUTO?qs=P%2FxahI%252BVehm4DIVfs7vRXA%3D%3D

If that can help, husky is alive and status led is blinking correctly.

Thank you so much for your support,

Shanly

That’s not a good sign: it means we’re not able to read properly from the PLL chip (U10). It’s close to C49, which suggests it may have been damaged. Here we should be reading [2, 0, 0], and you’re getting [1, 8, 0] instead.

The I2C lines which handle PLL communication are near the top right corner, on the backside, if you’re up to inspecting for damage and checking with a logic analyzer.

Hello,

We have done a optical inspection of the soldering, it seems to look fine ? Here are some picture for reference

We have tried reinstalling the drivers in the hopes of succeeding a firmware update but reinstalling the drivers did not change the issues so the CW is unavailable for any kind of firmware update.

Thank you for your suggestion. This kind of hardware debugging is really out of our competence set as it is, could you eventually please provide us with further guidance ? Is there any further output we can provide you with ?

Email sales@newae.com with a reference to this C49 modification and we’ll take the next steps from there.

Thank you for your swift support! The performances of the Husky have significantly improved.

Running the solution lab actually brings us to a output close to @vector247

The peaks are now clearly visible (solution peaks)

So, based on the precedent graph, I know that subkey 0 has a peak of around 0.4 at around 1900, which means it is the dark blue one. It stands particularly well at 2500 too.

With a brute windowing of [2500:]

Subkey 0 - most likely 0C (actual 2B)

Top 5 guesses:

0C - Diff = 0.002146

9F - Diff = 0.001743

CD - Diff = 0.001732

0B - Diff = 0.001723

26 - Diff = 0.001691

Subkey 1 - most likely 7E (actual 7E)

Top 5 guesses:

7E - Diff = 0.003172

6F - Diff = 0.001874

3F - Diff = 0.001803

19 - Diff = 0.001760

1F - Diff = 0.001724

Subkey 2 - most likely 15 (actual 15)

Top 5 guesses:

15 - Diff = 0.002919

B5 - Diff = 0.001939

DC - Diff = 0.001771

E6 - Diff = 0.001708

9A - Diff = 0.001681

Subkey 3 - most likely 16 (actual 16)

Top 5 guesses:

16 - Diff = 0.003997

AB - Diff = 0.002369

7D - Diff = 0.002168

8F - Diff = 0.002138

12 - Diff = 0.002023

Subkey 4 - most likely 17 (actual 28)

Top 5 guesses:

17 - Diff = 0.001870

8A - Diff = 0.001764

C8 - Diff = 0.001743

39 - Diff = 0.001697

20 - Diff = 0.001676

Subkey 5 - most likely AE (actual AE)

Top 5 guesses:

AE - Diff = 0.002839

BF - Diff = 0.001852

B9 - Diff = 0.001778

4B - Diff = 0.001716

3A - Diff = 0.001693

Subkey 6 - most likely D2 (actual D2)

Top 5 guesses:

D2 - Diff = 0.002999

B9 - Diff = 0.001864

BB - Diff = 0.001808

7C - Diff = 0.001801

91 - Diff = 0.001796

Subkey 7 - most likely A6 (actual A6)

Top 5 guesses:

A6 - Diff = 0.003777

4A - Diff = 0.002487

1B - Diff = 0.002405

CD - Diff = 0.002318

34 - Diff = 0.002312

Subkey 8 - most likely CC (actual AB)

Top 5 guesses:

CC - Diff = 0.002222

E0 - Diff = 0.001935

F3 - Diff = 0.001681

02 - Diff = 0.001678

EA - Diff = 0.001630

Subkey 9 - most likely F7 (actual F7)

Top 5 guesses:

F7 - Diff = 0.003574

7F - Diff = 0.002292

B5 - Diff = 0.001947

9C - Diff = 0.001926

06 - Diff = 0.001876

Subkey 10 - most likely 15 (actual 15)

Top 5 guesses:

15 - Diff = 0.003001

FB - Diff = 0.002578

35 - Diff = 0.002027

AF - Diff = 0.001811

52 - Diff = 0.001772

Subkey 11 - most likely 88 (actual 88)

Top 5 guesses:

88 - Diff = 0.003423

35 - Diff = 0.002113

E3 - Diff = 0.002094

E5 - Diff = 0.001994

7D - Diff = 0.001992

Subkey 12 - most likely 57 (actual 09)

Top 5 guesses:

57 - Diff = 0.001821

F4 - Diff = 0.001712

B1 - Diff = 0.001660

40 - Diff = 0.001632

DF - Diff = 0.001630

Subkey 13 - most likely CF (actual CF)

Top 5 guesses:

CF - Diff = 0.003567

A6 - Diff = 0.001885

72 - Diff = 0.001840

22 - Diff = 0.001680

A4 - Diff = 0.001647

Subkey 14 - most likely 4F (actual 4F)

Top 5 guesses:

4F - Diff = 0.003053

FC - Diff = 0.001882

27 - Diff = 0.001869

CF - Diff = 0.001854

2D - Diff = 0.001831

Subkey 15 - most likely 3C (actual 3C)

Top 5 guesses:

3C - Diff = 0.003877

81 - Diff = 0.002414

57 - Diff = 0.002140

C2 - Diff = 0.001997

C9 - Diff = 0.001954

We recovered almost all bytes! Except 0, 4, 8, and 12 (The +4 offset between each is intriguing aha). In those cases, the real key doesn’t make it to the top 5.

Windowing still remains quite difficult and we don’t get a perfect solution. I tried to optimize it with something like [(offset_start + cycle*subkey) : (offset_end + cycle*subkey)] and I cannot seem to find such parameters that give me something perfect. Do you have any suggestion on how to solve this?

On the other hand, Solution Lab for 4.2 worked perfectly so the main issue have been resolved on my side. A huge thanks to @Alex_Dewar, @jpthibault and other members of the NewAE team. Thanks also to the community for contributing to this topic and helping us get to the bottom of this issue!

Hello, bump because I saw the thread marked as incorrectly resolved (I don’t know if it was me or automatic) since I cannot recover the key for 0, 4, 8, and 12, is it a hardware or software issue ? The key doesn’t even make it to the top 5 and the cyclicity is intriguing.

Yeah, it certainly is very strange. Here’s the actual implementation of the SubBytes function:

// The SubBytes Function Substitutes the values in the

// state matrix with values in an S-box.

static void SubBytes(state_t* state)

{

uint8_t i, j;

for (i = 0; i < 4; ++i)

{

for (j = 0; j < 4; ++j)

{

(*state)[j][i] = getSBoxValue((*state)[j][i]);

}

}

}

My first thought is that maybe there’s something weird with the use of two indexes like this into the state array? CPA handles this byte fine, so the information is definitely there. I’m curious if there’s consistent lower correlation on these bytes vs j != 0.